Grinding solutions

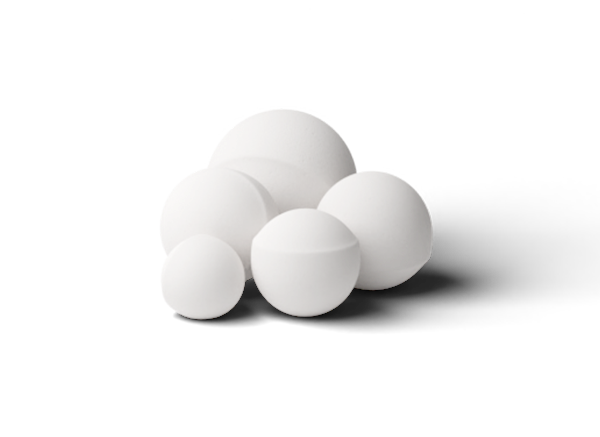

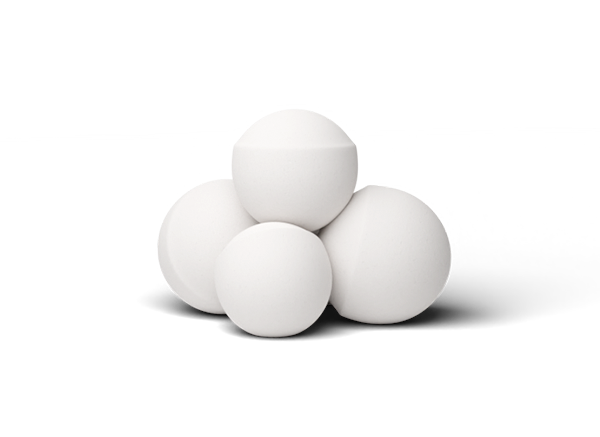

Alubit® Leonardo

Made in Italy

High-density alumina balls for continuous and discontinuous wet grinding mills.

see product

Alubit® Leonardo Dry

Made in Italy

High-density alumina balls for continuous and discontinuous dry grinding.

see product

Alubit® Leonardo Cylinders

Made in Italy

High-density alumina cylinders for discontinuous wet grinding mills and dry vibrating mills.

see product

Microbit Leonardo / Leonardo SM

Made in Italy

High-density alumina microbeads for the micronization of minerals in continuous and discontinuous axial and attritor mills.

see product

Microbit Leonardo ZTA

Made in Italy

High-density alumina microbeads reinforced with zirconium for the grinding of minerals and precious metals in attritor mills.

see product

By periodically visiting customers, Industrie Bitossi staff gathers information regarding the technical characteristics of the grinding plant to seek solutions that can contribute to improving productivity and reducing industrial costs.

WORKING CONDITIONS AND RAW MATERIALS PROCESS ANALYSIS

Working conditions and technical parameters that can have a significant impact on mill performance are carefully analysed. Special attention is given to the sizing of the alumina balls composing the Alubit Leonardo grinding charges in relation to the characteristics of the raw materials and machines used. This in-depth study aims to achieve the following results:

- reduction of grinding time

- increase in mill productivity

- reduction of grinding media and lining consumption

- reduction of cost associated with the grinding process

TECHNICAL SIMULATIONS / CUSTOMER SUPPORT::

At the company's laboratories and facilities it is possible to perform chemical and granulometric analyses, as well as actual grinding simulations using raw materials provided by the customer. This makes it possible to quickly identify the characteristics of the materials to be ground and, consequently, the ideal composition of Alubit® Leonardo grinding charges to be used.

Wear resistant solutions

Alubit® 90

Made in Italy

Alubit 90 linings sets are designed on AutoCAD and shaped by CNC machines to ensure maximum installation precision and an excellent wear rate. For the wear-resistant protection of wet batch mills and dry continuous mills.

see product

Duralbit 92 / 96 / 98

Made in Italy

Wear-resistant linings for the protection of metal parts of cyclones, separators, hoppers, pipes and silos.

see productThe installation of Alubit® 90 alumina linings in continuous dry mills and discontinuous wet mills could be considered a simple construction job. However, it is a complex process that involves the use of techniques acquired in over fifty of experience in the industry.

Petrochemical industry

Supporbit

Made in Italy

High-density sintered alumina inert balls, suitable for catalyst supports in petrochemical plants, gas treatment, solvent and heat recovery and fertiliser production.

see productZIRCONIUM

SILICATE

Industrie Bitossi selects the best “premium grade” zircon sands and state-of-the-art grinding technology to produce zircon flours and micronized zirconium silicate used in the ceramic, refractory and investment casting industries.

FIND OUT MORE

PROTECTIVE

CERAMIC

Industrie Bitossi produces technical ceramic components for armor applications. Our products are available in a wide variety of shapes and sizes.

FIND OUT MORE

Would you like more information?

Contact us

Leading the way in ceramics,

for over sixty years.

RESEARCH, DEVELOPMENT AND CONTROL ARE THE CORNERSTONES

OF BOTH OUR PAST AND OUR FUTURE.